Refractory Classification: What Are Refractory Shapes?

Loka Refractories - Refractories are heat and fire resistant materials. Currently, these materials are needed by many industrial sectors in Indonesia, such as fertilizer, paper, food, and many more.

There are various types of refractories and are classified into several groups. One of them is based on shape.

According to the shape, the refractory material consists of shaped refractories, unshaped refractories, and fibrous material.

Types of Refractory Based on Shape

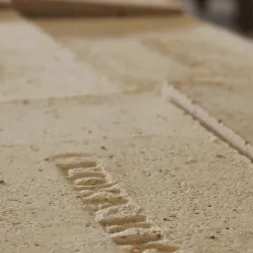

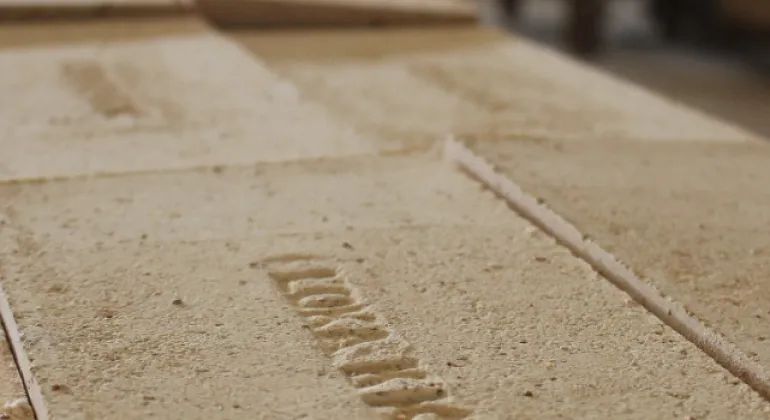

1. Shaped refractories

Shaped refractories are refractory materials that go through a forming process with a high pressure press machine so that they have a definite shape.

Typically, shaped refractories or also known as bricks are applied to furnaces, kilns, glass tanks, or lining incinerators.

2. Unshaped refractories

In contrast to shaped refractories, unshaped refractories do not go through a process of forming with a press machine so they don't have a definite shape.

Unshaped refractories or can also be called monolithic refractories have several types including Mortar, Castable, Plastic, Gunning and Ramming Mix, and many more.

3. Fibrous Material

Ceramic fiber, a type of fibrous material are refractory materials in the form of synthetic fibers. Several kinds of fibrous materials include blankets, felt, modules, vacuum forms, rope and loose fiber.

Special Shaped Refractory

Thus the type of refractory based on shape. But, those aren't the only existing refractory shapes.

In fact, there are refractory materials that have customized shapes based on the industries' requirements.

Where could we find customized shaped refractories, you ask?

Loka Refractories is here to supply the industries' need of shaped, unshaped, even special refractories!

Call us!

Loka Refractories

E-mail : info@lokarefractories.com

Phone : 031-7663307

Whatsapp : 0821-4280-8500

There are various types of refractories and are classified into several groups. One of them is based on shape.

According to the shape, the refractory material consists of shaped refractories, unshaped refractories, and fibrous material.

Types of Refractory Based on Shape

1. Shaped refractories

Shaped refractories are refractory materials that go through a forming process with a high pressure press machine so that they have a definite shape.

Typically, shaped refractories or also known as bricks are applied to furnaces, kilns, glass tanks, or lining incinerators.

2. Unshaped refractories

In contrast to shaped refractories, unshaped refractories do not go through a process of forming with a press machine so they don't have a definite shape.

Unshaped refractories or can also be called monolithic refractories have several types including Mortar, Castable, Plastic, Gunning and Ramming Mix, and many more.

3. Fibrous Material

Ceramic fiber, a type of fibrous material are refractory materials in the form of synthetic fibers. Several kinds of fibrous materials include blankets, felt, modules, vacuum forms, rope and loose fiber.

Special Shaped Refractory

Thus the type of refractory based on shape. But, those aren't the only existing refractory shapes.

In fact, there are refractory materials that have customized shapes based on the industries' requirements.

Where could we find customized shaped refractories, you ask?

Loka Refractories is here to supply the industries' need of shaped, unshaped, even special refractories!

Call us!

Loka Refractories

E-mail : info@lokarefractories.com

Phone : 031-7663307

Whatsapp : 0821-4280-8500

Latest Article