Refractory Materials: Definition, Use, and Application

Loka Refractories - Refractory materials can be said to be the breath of industries that use heat energy directly or indirectly.

So, what is refractory and what are their use and applications? Read the article below!

What is refractory material?

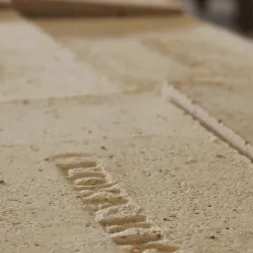

Refractory is a material that can maintain its physical form and chemical content after being exposed to high heat for a relatively long time. If translated literally, refractory means something that is stubborn.

Not only in language, there are several definitions of refractory including:

1. According to ASTM 71, a refractory is defined as a non-metallic material which has the chemical and physical properties that can be used for structure or as a component of a system, which is in an environmental temperature above 1000 °F (811 °K; 538 °C) .

2. According to JIS R 2001-1985, refractory is a material with a fixed shape that is durable at high temperatures (> 1500 °C) and shapeless materials (mortar, castable, plastic, etc.) and refractory bricks with a usage temperature of > 800 ° C.

Why are refractory materials needed?

The function of the refractory is not limited to holding high temperatures, including:

1. Protects the walls of the reactor/furnace against high temperatures, hot gases, catalysts, melts and solvents. So that the lifetime becomes longer;

2. Reducing heat loss or heat coming out of the furnace, boilers, and kilns;

3. Maintaining the stability of the operating temperature in the equipment;

4. Protect workers from the threat of high heat.

After knowing about the refractory function, you must be curious about its application, right?

No need to worry! Just scroll down a little bit and you will know how refractory materials are used.

The Application of Refractory Materials

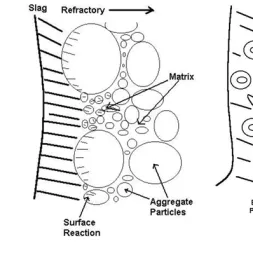

Refractory can be applied to linings in thermal processes (melting, firing, heat-treatment furnaces) for the metal and non-metal industries.

In the metallurgical industry, a refractory material is applied to the inner lining of the tool to contain and convey metal and slag.

Whereas in the non-metal industry, refractory is applied to fired heaters, hydrogen reformers, catalytic cracking units, coke calciners, sulfur furnaces, air heaters, ducting, chimneys, and the like.

In addition to the explanation above, refractory is also used as heat insulation, or as a heat sink so it doesn't come out of the tool.

Refractory materials consist of various kinds according to the needs of the application.

How could we find refractory materials?

Indonesia has a lot of refractory material manufacturers. But how could we find the best refractory materials that required for our industry?

If that’s what you’re looking for, just call Loka Refractories! We will supply best quality materials that can be customized as per your requirements to keep your business going.

You can submit your inquiry to:

Loka Refractories

E-mail : info@lokarefractories.com

Phone : 031-7663307

Whatsapp : 0821-4280-8500

So, what is refractory and what are their use and applications? Read the article below!

What is refractory material?

Refractory is a material that can maintain its physical form and chemical content after being exposed to high heat for a relatively long time. If translated literally, refractory means something that is stubborn.

Not only in language, there are several definitions of refractory including:

1. According to ASTM 71, a refractory is defined as a non-metallic material which has the chemical and physical properties that can be used for structure or as a component of a system, which is in an environmental temperature above 1000 °F (811 °K; 538 °C) .

2. According to JIS R 2001-1985, refractory is a material with a fixed shape that is durable at high temperatures (> 1500 °C) and shapeless materials (mortar, castable, plastic, etc.) and refractory bricks with a usage temperature of > 800 ° C.

Why are refractory materials needed?

The function of the refractory is not limited to holding high temperatures, including:

1. Protects the walls of the reactor/furnace against high temperatures, hot gases, catalysts, melts and solvents. So that the lifetime becomes longer;

2. Reducing heat loss or heat coming out of the furnace, boilers, and kilns;

3. Maintaining the stability of the operating temperature in the equipment;

4. Protect workers from the threat of high heat.

After knowing about the refractory function, you must be curious about its application, right?

No need to worry! Just scroll down a little bit and you will know how refractory materials are used.

The Application of Refractory Materials

Refractory can be applied to linings in thermal processes (melting, firing, heat-treatment furnaces) for the metal and non-metal industries.

In the metallurgical industry, a refractory material is applied to the inner lining of the tool to contain and convey metal and slag.

Whereas in the non-metal industry, refractory is applied to fired heaters, hydrogen reformers, catalytic cracking units, coke calciners, sulfur furnaces, air heaters, ducting, chimneys, and the like.

In addition to the explanation above, refractory is also used as heat insulation, or as a heat sink so it doesn't come out of the tool.

Refractory materials consist of various kinds according to the needs of the application.

How could we find refractory materials?

Indonesia has a lot of refractory material manufacturers. But how could we find the best refractory materials that required for our industry?

If that’s what you’re looking for, just call Loka Refractories! We will supply best quality materials that can be customized as per your requirements to keep your business going.

You can submit your inquiry to:

Loka Refractories

E-mail : info@lokarefractories.com

Phone : 031-7663307

Whatsapp : 0821-4280-8500

Latest Article