Monolithic Refractory Inspection Methods

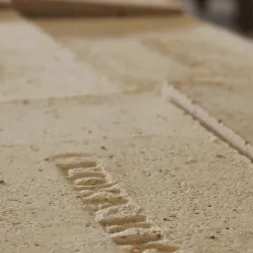

Every time you install refractory material, an inspection needs to be carried out afterwards. The aim is to ensure that the installed materials comply with the specified conditions and comply with the design that has been made.

Refractory inspection methods vary according to type. In this article we will explain inspection methods for monolithic or unformed refractories such as castables, mortars and so on.

Monolithic refractories are inspected using two methods, namely visual inspection and lining inspection for pressure vessels. Check out the explanation below!

Visual Inspection

Some visual inspection methods include the following:

1) Cover Joint Inspection

Check that the mortar or seal between the packings has been packed between the joints properly.

2) Dimensional Inspection

Check dimensions carefully, especially locations where dimensional accuracy must be maintained (e.g. joints with accessories).

3) Repair

If the inspection finds repairs, follow-up with repairs is required after removing the damaged refractory from the repair location. Remove the castable properly to allow the anchor to support the installation of the new refractory.

Some things to pay attention to include:

1. Make sure that the removal does not affect the surrounding normal lining. Also ensure that there are backup materials in case any are damaged by demolition.

2. Clean the area after dismantling the refractory. Replace with only castable of the same type. Also before reinstalling the castable, use fresh water to wet the area ready to be installed that contacts the new castable.

3. To fix the lining, generally the same installation method is used for large areas in the same way as when the initial refractory was installed.

Layer Inspection for Pressure Vessels

Lining inspection for pressure vessels can be carried out using visual or sound waves, and hammer tests.

This inspection is carried out after natural drying and dryout. If necessary, x-rays or other non-destructive tests may be performed for particularly important areas.

Lining inspection methods for pressure vessels include:

1. Inspection after natural drying (24 hours after installation)

a) Ensure that the lining workmanship is satisfactory.

b) Check if there is any reflective material still attached to the gunning surface.

c) Check for cracks.

d) Check dimensions.

2. Hammer Test

The hammer test refers to striking the lining with a hammer, at approximately 300mm intervals to ensure from sound that the lining is installed satisfactorily.

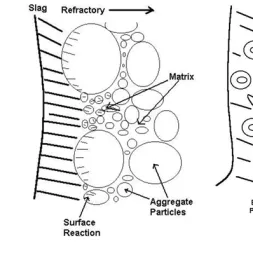

The hammer test is aimed primarily at determining that there is no reflective material attached to the lining being gunned, there are no laminations on the lining that cause peeling, the refractory castable is in contact with the cells and there is empty space in the refractory.

If your company needs a monolithic refractory for applications in furnaces, boilers and kilns, contact us at:

Phone: 0821-4280-8500

E-mail : info@lokarefractories.com

Refractory inspection methods vary according to type. In this article we will explain inspection methods for monolithic or unformed refractories such as castables, mortars and so on.

Monolithic refractories are inspected using two methods, namely visual inspection and lining inspection for pressure vessels. Check out the explanation below!

Visual Inspection

Some visual inspection methods include the following:

1) Cover Joint Inspection

Check that the mortar or seal between the packings has been packed between the joints properly.

2) Dimensional Inspection

Check dimensions carefully, especially locations where dimensional accuracy must be maintained (e.g. joints with accessories).

3) Repair

If the inspection finds repairs, follow-up with repairs is required after removing the damaged refractory from the repair location. Remove the castable properly to allow the anchor to support the installation of the new refractory.

Some things to pay attention to include:

1. Make sure that the removal does not affect the surrounding normal lining. Also ensure that there are backup materials in case any are damaged by demolition.

2. Clean the area after dismantling the refractory. Replace with only castable of the same type. Also before reinstalling the castable, use fresh water to wet the area ready to be installed that contacts the new castable.

3. To fix the lining, generally the same installation method is used for large areas in the same way as when the initial refractory was installed.

Layer Inspection for Pressure Vessels

Lining inspection for pressure vessels can be carried out using visual or sound waves, and hammer tests.

This inspection is carried out after natural drying and dryout. If necessary, x-rays or other non-destructive tests may be performed for particularly important areas.

Lining inspection methods for pressure vessels include:

1. Inspection after natural drying (24 hours after installation)

a) Ensure that the lining workmanship is satisfactory.

b) Check if there is any reflective material still attached to the gunning surface.

c) Check for cracks.

d) Check dimensions.

2. Hammer Test

The hammer test refers to striking the lining with a hammer, at approximately 300mm intervals to ensure from sound that the lining is installed satisfactorily.

The hammer test is aimed primarily at determining that there is no reflective material attached to the lining being gunned, there are no laminations on the lining that cause peeling, the refractory castable is in contact with the cells and there is empty space in the refractory.

If your company needs a monolithic refractory for applications in furnaces, boilers and kilns, contact us at:

Phone: 0821-4280-8500

E-mail : info@lokarefractories.com

Latest Article