Refractory Bricks Classification Based On Quality Standard

There are many classifications of refractory materials. These include based on shape, properties, composition, and so on.

In this article, we will discuss the classification of refractory bricks based on quality standards.

The quality standards for refractory bricks refer to the standards issued by American Standard Testing and Materials or ASTM International.

So, what are the classifications based on ASTM International quality standards? Check out the explanation below!

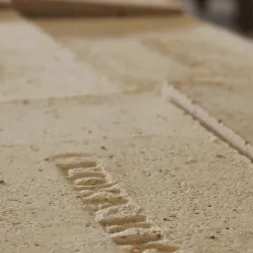

Silica Brick (C 416-97 ASTM)

The composition of Silica Brick is as follows:

a) AI₂O₃ < 1.5 %

b) TiO₂ < 0.2 %

c) Fe₂O₃ < 2.5%

d) CaO < 4.0 %

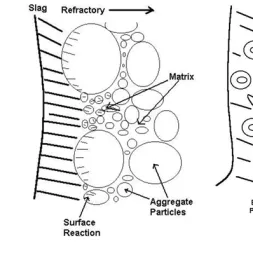

The presence of contaminants in silica bricks tends to reduce refractoriness and their use is limited.

The amount of alkali and alumina can be used to estimate refractoriness properties.

Silica Bricks are classified based on impurities and usually called flux factor.

Alumina Silicate (fire clay) and high alumina bricks (C 27-98 ASTM)

Alumina-silica Refractory Bricks are produced from various combinations of alumina and silica grades.

The variation in chemical composition is quite wide, ranging from almost 100% alumina with a little silica, to almost 100% silica with a little alumina.

Classification based on chemical composition and physical properties consists of:

1. Fire clay bricks are classified based on physical properties, which can be an overlap between alumina and silica content:

Super-duty, High-duty, Semi-silica, Medium-duty, and Low-duty.

2. High alumina bricks are classified based on alumina content: 50, 60, 70, 80, 85, 90, and 99%.

Schamotte Insulating Brick (Insulating Fire Brick)

The classification of heat insulating materials is known as samot insulating brick (insulating fire brick). This insulating material is suitable for lining certain types of industrial furnaces.

AI₂O₃ - SiO₂ Insulation Brick (fire brick) ASTM C 155 - 97 is classified as follows:

|

Kelas |

Shrinkage max 2% on Temp°C |

Bulk Density max Lb/ft3 (g/cm3) |

|

16 |

845 |

0,54 |

|

20 |

1065 |

0,64 |

|

23 |

1230 |

0,77 |

|

26 |

1400 |

0,86 |

|

28 |

1510 |

0,96 |

|

30 |

1620 |

1,09 |

|

32 |

1730 |

1,52 |

|

33 |

1790 |

1,52 |

Call us and get your high quality fire bricks!

Phone: 0821-4280-8500

E-mail : info@lokarefractories.com