Refractory Failure: Spalling

Did you know about refractory failure?

Refractory materials installed in a furnace will be in contact with extreme environments such as high temperatures and high pressure. Therefore, refractory failure can happen if the right material is not used.

There are many types of refractory failure caused by various factors. One of the most common things that occurs is spalling. What is spalling and what causes it? Check out the explanation below!

What is Spalling?

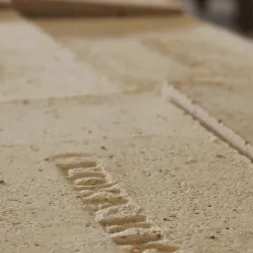

Spalling is the release of part of the material from its parent due to internal pressure (stress) of the material in response to changes in environmental conditions. Usually, spalling starts from the appearance of cracks or splitting of the installed material.

There are three types of spalling with different causes, namely thermal spalling, structural spalling, and mechanical spalling.

Types of Spalling

Thermal spalling is material damage by temperature shock which results in temperature differences that cause stress.

Damage occurs through the formation of initial cracks due to stress caused by temperature shock which is greater than the strength of the material and is followed by crack propagation.

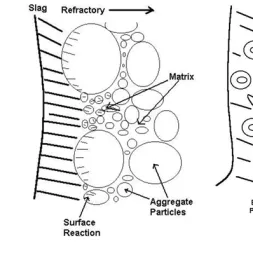

Structural Spalling is spalling caused by changes in phase (mineralogy, form), so that differences in the properties of the changed and original parts cause internal stress.

Structural spalling is caused by overheating and chemical reactions/penetration.

Structural spalling caused by overheating can be prevented by:

- Temperature control

- Control of intake air or furnace atmosphere

- Selection of appropriate refractory

Meanwhile, those caused by chemical reactions and penetration are prevented by:

- Selection of refractory materials according to the nature of the environment in the furnace (acid, neutral, alkaline)

- Arrangement of porosity, pore size distribution, wettability, etc.

Mechanical Spalling is a failure that is often caused by concentrated loads due to unequal distribution of mechanical forces.

One of them is the lining design on the refractory and metal connections such as steel anchors, and on the masonry in the furnace arc. Another cause is the use of inappropriate materials.

Spalling or other refractory failures can be prevented by selecting refractory materials with the right specifications and good quality.

Get the best quality refractory materials from Loka Refractories! Contact us for our best offer!

Phone : 0821-4280-8500

E-mail: marketing@lokarefractories.com

Image source :

https://link.springer.com/article/10.1007/s11661-011-0635-x/figures/13

Refractory materials installed in a furnace will be in contact with extreme environments such as high temperatures and high pressure. Therefore, refractory failure can happen if the right material is not used.

There are many types of refractory failure caused by various factors. One of the most common things that occurs is spalling. What is spalling and what causes it? Check out the explanation below!

What is Spalling?

Spalling is the release of part of the material from its parent due to internal pressure (stress) of the material in response to changes in environmental conditions. Usually, spalling starts from the appearance of cracks or splitting of the installed material.

There are three types of spalling with different causes, namely thermal spalling, structural spalling, and mechanical spalling.

Types of Spalling

Thermal spalling is material damage by temperature shock which results in temperature differences that cause stress.

Damage occurs through the formation of initial cracks due to stress caused by temperature shock which is greater than the strength of the material and is followed by crack propagation.

Structural Spalling is spalling caused by changes in phase (mineralogy, form), so that differences in the properties of the changed and original parts cause internal stress.

Structural spalling is caused by overheating and chemical reactions/penetration.

Structural spalling caused by overheating can be prevented by:

- Temperature control

- Control of intake air or furnace atmosphere

- Selection of appropriate refractory

Meanwhile, those caused by chemical reactions and penetration are prevented by:

- Selection of refractory materials according to the nature of the environment in the furnace (acid, neutral, alkaline)

- Arrangement of porosity, pore size distribution, wettability, etc.

Mechanical Spalling is a failure that is often caused by concentrated loads due to unequal distribution of mechanical forces.

One of them is the lining design on the refractory and metal connections such as steel anchors, and on the masonry in the furnace arc. Another cause is the use of inappropriate materials.

Spalling or other refractory failures can be prevented by selecting refractory materials with the right specifications and good quality.

Get the best quality refractory materials from Loka Refractories! Contact us for our best offer!

Phone : 0821-4280-8500

E-mail: marketing@lokarefractories.com

Image source :

https://link.springer.com/article/10.1007/s11661-011-0635-x/figures/13

Latest Article